QTD luffing tower crane

Model No.︰QTD

Brand Name︰-

Country of Origin︰China

Unit Price︰US $ 30000 / pc

Minimum Order︰1 pc

Product Description

QTD125(5025) 12t luffing jib tower crane features stable operation and reliable management due to the adoption of various advanced technologies. It is configured with diverse devices like the hydraulic self-propelling device, frequency converting slewing device and a series of reliable safety devices like hoisting height limiter, slewing range limiter and multifunctional limiter. It is thus easy for this heavy lifting equipment to control the hoisting capacity, load moment and trolley traveling range more precisely. Additionally, multiple electric safety devices such as anemoscopes and obstacle lights effectively prevent the breaking of trolley axles and wire ropes.

The PLC (Programmable Logic Controller) adopted by our aerial equipment can timely diagnose the cause of breakdowns. The frequency converter easily realizes continuously variable speed regulation and greatly improves the stability, reliability, and operability of the control system as well as the work efficiency of the flat top tower crane. In addition, the electric components are introduced from world-class enterprises including Omron, YASKAWA, Schneider (TE) and MEAN WELL. They ensure a low failure rate of the electric control system.

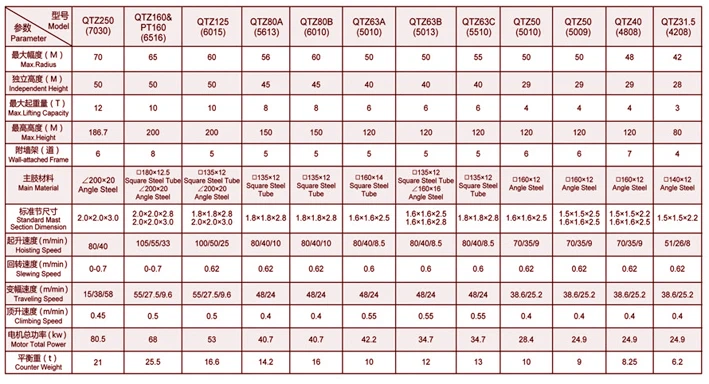

Technical Parameters of crane machine /qtzd125(5025) 12t luffing jib tower crane

Features of crane machine /qtzd125(5025) 12t luffing jib tower crane

1. The tower crane comprises a number of mast sections that are highly interchangeable. The elaborate structure makes it easy for mounting and dismounting.

2. The main support of the mast section has both end faces processed by the jig boring machine to live up to the required flatness of both ends and verticality of the whole mast section, thereby improving the overall performance of the tower crane.

3. The metal parts are jointed by carbon dioxide gas shielded arc welding to achieve a tough and reliable structure.

4. Product quality is further guaranteed by the advanced inspection devices, such as the ultrasonic fault detector and sound level meter.

5. A complete set of safe and reliable hydraulic jacking device is adopted for self-elevating. The tower crane goes up and down steadily and the lifting height varies with the building height. These merits make the lifting equipment ideal for high-rise construction.

6. The cargo boom with triangular cross-section performs with double lifting points. It features excellent rigidity and convenient installation.

7. The hoisting mechanism provides slow dropping of large load in position as well as prompt lifting and dropping for small load. Thus the working efficiency is significantly improved. The lifting speed reducer is purchased from notable manufacturers to ensure that the tower crane works stably with low noise and high reliability.

8. Our self-erecting crane makes use of the single row four-point contact slewing bearing manufactured via advanced process by Hoesch Rothe Erde in Germany. This slewing bearing offers fine rigidity as well as excellent bearing ability of axial and radial tilting torque.

9. The slewing device comprises hydraulic coupling and planetary gear reducer, thus it enjoys high torsional capacity, high transmission ratio, compact structure, steady operation, and low failure rate.

10. The speed of the hoisting mechanism and the slewing device can be regulated by the winding wire motor and resistor to smooth the moving process and also prolong the serving time of the tower crane.

11. The components of electrical system are made by well-known enterprises in China and they are stable and reliable in performance.

Payment Terms︰ TT / LC